We are Pioneer of Innovative Solutions

Hydro Electric Energy for the Next generations

Anti-Drone Technology

LTV Waste water Treatment system technologies

Hydro Electric Energy for the Next generations

Being a torch bearer of sustainability and innovation in the global industry, we have always focused on further developments in the technology and for that purpose we have been working on various projects.

Hydro power is the process of generating power or electricity through falling water that ultimately runs the turbines of the plant. Basically with the help of gravity, when the water falls from a height on the motors, the shaft starts rotating and the power begins to generate in result.

Mostly this process is designed and implemented on Dams where abundant water resources can be effectively used to generate significant amount of hydro power. Dams have always been a source of water supply for mankind for centuries and have saved many economies from collapse through water shortage.

The first known dam was constructed in Egypt more than 5,000 years ago, the idea was simple and the construction took years. The effects of this dam were enormous. It built Egypt and saved its people from starvation. Without specifics, math equates that this dam could have produced about 12 MW of power per day.

But things have not changed in this regard for last 5000 years!

Today, the Three Gorges Dam in China is King, with its size and energy output of just over 22,500 MW. The turbines used in this dam are very similar to those used in the first Hydroelectric Dam in Appleton Wisconsin. The cost, size and time it has taken to produce this dam cannot be offset. At just over 10 years of construction, the lost power is greater than the gained power.

How Dams are affecting our environment?

Because a dam takes advantage of gravity more than anything, the dam has to collect water above and release it below. This causes a lake or reservoir above the dam and under currents below. This means that the currents are eliminated above the dam and dramatically increased below. Also, because the currents below are releases at the base of the riverbed they are even more damaging to the ecosystem of the river. These effects are felt 2 miles before the dam and 10 miles below it.

How the Hydropower is generated traditionally?

Our brokers can help you find the best market price which exactly matches your current market needs and save you a lot of your precious time.

Our brokers are the magnets of the real estate industry who follow current industry and global economic trends and point out the recent sales in the prospective area of your surroundings. They can even list your property on the listing websites but the listing price has room for negotiation with potential buyers.

Dam alternative for Hydropower

First used in the 1950’s and widely considered to be the next step in energy production, “Dam Free” technology is new. Most “Dam Free” systems produce too little energy with too great of a cost. Most “Dam Free” systems use the power of the current and/or tide to spin mini-turbines and produce power. These are simple but very inefficient as they produce very little power. Effectively efficient is the next step in “Dam Free” Hydro Electric turbines.

- Some stats and facts are given below

- Take about 2-5 years to construct

- Eliminate fish downstream for up to 10 miles

- Eliminate shipping lanes

- Eliminate hatcheries and spawning grounds

- Erodes the shoreline and plains surrounding the river

- Deposits damaging sediments below the dam

- Produces hazardous bacteria above the dam

- Can never be removed without 10-20 year plan for recovery

Cost analysis

Cost about $1,200.00 USD per KW to install and $1,800 to remove, In recent studies by the Army Corp of Engineer. Average cost per KW of energy produced in the US costs $1,211.00 for the construction of a dam (Calculated on 12 dams ranging from 3,700 MW to 10,000 MW). Average cost to remove a dam and return the river to its original condition is $1,834.00 per KW (Calculated on a 10,000 MW dam)

Why generate power at the surface?

As water pushes towards the surface it has fewer directions to release its energy. This means that the water that is at the surface on a river is running in the downward slope of the river bed and is compressed more for greater energy. Placing a generation system at the surface in a river is a 50% increase in available energy. At the base or bottom of the river the energy stored is very low. It is all released upward and lost or converted by moving the sand, rocks and plant life. As the water is pushed upward the energy builds and at the surface it is at its maximum and ready for use.

Our Innovative initiative

Our “Water Walker” floats on the surface of the water to collect the energy at the surface of the water. Because it floats it always gathers the maximum amount of energy without any impact on the river and the environment. Because it floats it raises and lowers with the rainfall and does not need constant adjustment. Most water turbines use one system to collect and produce energy while we use four ~ System 1: The “Water Walker” By driving just two piles or casings into the riverbed, there is now a platform for anchoring the “Water Walker”. Our “Water Walker” floats on the surface and it’s uniquely designed fins channel the water and collect the maximum amount of energy and release it into the shafts at each side of the unit.

Our Pressure jet system is very promising

Most water turbines use one system to collect and produce energy while we use four ~ System 4: The “Pressure Jets” The water that is being released to shore at 90 PSI is fed directly into the pressure jets. Each “Water Walker” has a “Pressure Jet” and each jet is mounted on shore. Each jet has the direct feed of electricity from the “Frictionless Generators” and has the output which is a combination of both systems. The water is not concentrated and blasted into a turbine that splits the jet of water and spins a turbine at a rate of 1,800+ RPMs and spins a shafts running through the turbine. At the end of each shaft are magnetic fins which again are centered in 100 HP magnetic field generators. The energy produced is fed out to the grid.

Building Pressure for More Energy

When the water enters the jet turbine it is at 90 psi and ready to energize the turbine, but as it enters the diameter of the incoming pipes are reduced so even greater pressure is reached when the jets of water hit the turbine scoops. The scoops are also split to allow for an instant release of this pressure in order to capture maximum energy from each jet of water. The water then falls to the bottom and is discharged through drain pipes back into the river without loss of volume.

Design and Manufacturing

It is designed to be placed in the river and to become part of the river, letting the river lose nothing but give so much. In a 200’ wide river, we could install 200 units and produce 60 WM of electricity and still leave an 80’ wide shipping and fishing lane down the middle of the river. Unlike any other system, Hydro NRG is cheaper as it increases in volume. If we use 300 units the cost per KW of electricity produced is lower than 200 units. Further to this, as the currents increase and the rate of flow for the rivers increase, the cost of the electricity decreases because the output increases. Our product is the most cost effective way to harness the power of water without damaging the life of the water.

Key Attributes

- Entire system uses an 8’ x 8’ surface area of the river

- System uses an 8’ x 8’ area on the shoreline

- The 4 x 100 HP generators produce 300 KW of Electricity

- Installation takes just 3 – 4 weeks (depends on location)

- Installation can be “In River” or “On Shore”

- The unique design allows for “staircase” installation

- Nothing is as inexpensive as Nuclear and Modern Dam electricity, but nothing is as damaging to our environment.

- Our product costs much less to construct and produces nearly twice the electricity as a competitors “Dam Free” system

- Our product has only two point of maintenance and has a life-cycle of 30-50 years (with proper maintenance)

- Our product pays for itself and has a break-even point (where the cost of the unit is paid for by the selling of the electricity produced) of 3-4 years

- No fish or wildlife are harmed or can be harmed by Hydro NRG

- Our product NRG does not redirect any current in the river

- Our product has a time to operation of 6 weeks, others are 36 weeks

Unique Design

Cost Less

Anti-Drone Technology

LTV is a leader of authoritative projects and we design and produce anti-drone systems for neutralization and verification and identification of spy drones.

Anti-drones systems are used for protecting sensitive assets, detect unwanted drones on specific sites and monitor the security measures from the air. They are primarily designed for airports, military stations, and war sites, large public sites like stadiums, and critical construction sites.

LTV is a leader of authoritative projects and we design and produce anti-drone systems for neutralization and verification and identification of spy drones.

We have managed to formulate a structure that manufactures multi-layer and modular anti drones related items and we provide protection to airports, national events, and military operations.

LTV enables governments and municipalities to detect and destroy unwanted and spying drone attacks.

As the drone technology is being updated, we also practice innovating our existing protection and production system delivering a comprehensive approach towards the growing drone industry. As a global leader of technology, LTV provides complete service not only till procurement and installation but also through maintenance, update, and upgrades.

LTV Waste Water Treatment System Technologies

LTV in one of its many innovative projects, has decided to initiate leading the world in this field too. Our innovative processes are robust, dynamic, easily usable and high performing. How it works:

Waste water has affected our eco-system in a number of ways. It has damaged the marine life, fresh water resources and the animals and wild life related to the lakes, ponds and rivers. Industrialization gave humankind many captivating prizes but in return, it took a lot too. It almost destroyed natural habitat causing global warming, water exploitation and air pollution etc.

Water resources have been compromised since the advent of twentieth century and some countries are about to face a serious water crisis too.

During this calamities, LTV has urged the industrial community to protect our natural water resources to save the future of mankind. With the increasing fresh water demand, the need of existing water’s purification is also on peak.

LTV in one of its many innovative projects, has decided to initiate leading the world in this field too. Our innovative processes are robust, dynamic, easily usable and high performing.

How it works:

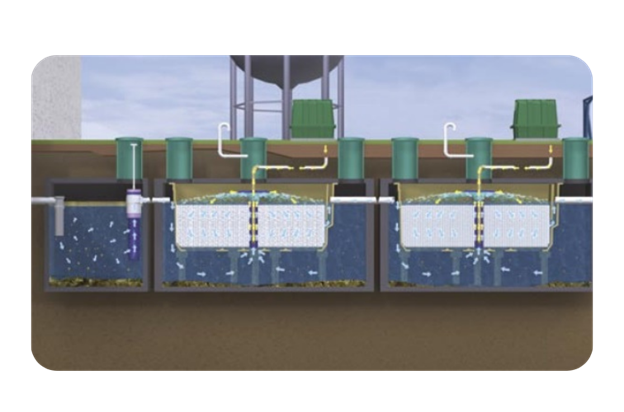

Our process employs a unique hybrid combination of attached and suspended growth in an aerobic, packed bed bioreactor. This proven IFAS (Integrated Fixed-Film Activated Sludge) combination includes the stability of fully-submerged, fixed-film media and the effectiveness of activated sludge treatment, making our innovative technology advanced and extraordinarily reliable.

A remote-mounted, above-ground blower, the systems only moving part, introduces air (oxygen) into the system to facilitate a robust circulation of wastewater through the media’s channeled flow path. Eventually, the robust circulation of air and liquid through the system creates a sloughing effect on the thick biomass growth, which creates a self-cleaning action, eliminating the need for any media maintenance.

Sloughed solids then settle to the bottom of the tank for later removal. High levels of bacteria and other useful microbes (including stalked ciliates and rotifers) in the bioreactor aeration zone provide stable operation, break down biodegradable constituents in the wastewater, prevent bulking conditions and settling problems, and yield a significantly longer sludge age than conventional plants. A long sludge age achieves nitritrication and denitrification much easier, operates more effectively in cold climates, and produces less sludge.

guarantee maximum performance

LTV has the Research & Development, leadership and innovative technologies that guarantee maximum performance and removal efficiencies. LTV’s Wastewater Treatment Systems are the “CLEAR” choice for all your waste removal applications.

Products are made with 100% corrosion resistant materials and contains post-consumer recycled materials. The extraordinarily high treatment levels may allow reductions in drain field areas, use of treated water for irrigation or other innovative discharge methods.